Managing Manufacturing and Supply Chain Challenges in LED Luminaire Design by Sanmina

Today’s luminaires are often complicated lighting systems and have a wide range of applications from in-home luminaires and retail to very high power outdoor lighting. This causes several challenges in both design and manufacturing. Some of these problems may have already been solved by design and manufacturing firms having expertise with LED luminaire design and manufacturing. Gelston Howell, Senior Vice President at Sanmina explains how to manage some of these design, manufacturing and supply chain challenges by using examples.

While large luminaire companies have outsourced production to contract manufacturing firms for some time, these companies are now outsourcing product design as well. Contract manufacturers and design firms now provide custom design, component selection and supply chain management services as well as manufacturing and test expertise to enable LED lighting OEMs to overcome the technical challenges associated with bringing LED luminaires to market. Moreover, these luminaire companies in some cases depend on EMS (Electronic Manufacturing Services) companies to provide complex technology solutions for luminaire designs to solve unique challenges. For example, unique heat sinking technologies have been developed by EMS companies with expertise in PCB (Printed Circuit Board) technology and thermal design, leveraging experience from other industries in the design of high power LED luminaires. Luminaire companies are often surprised at the depth of technical expertise and range of services provided by EMS and design firms. This design experience, along with global supply chain and manufacturing services, provide LED luminaire companies with a complete solution for complex LED light product design and manufacture.

Design and Technology Challenges with LED Lighting Products

Heat dissipation, design for cost and manufacturability, along with test systems development are some of the most common issues luminaire companies face with new products.

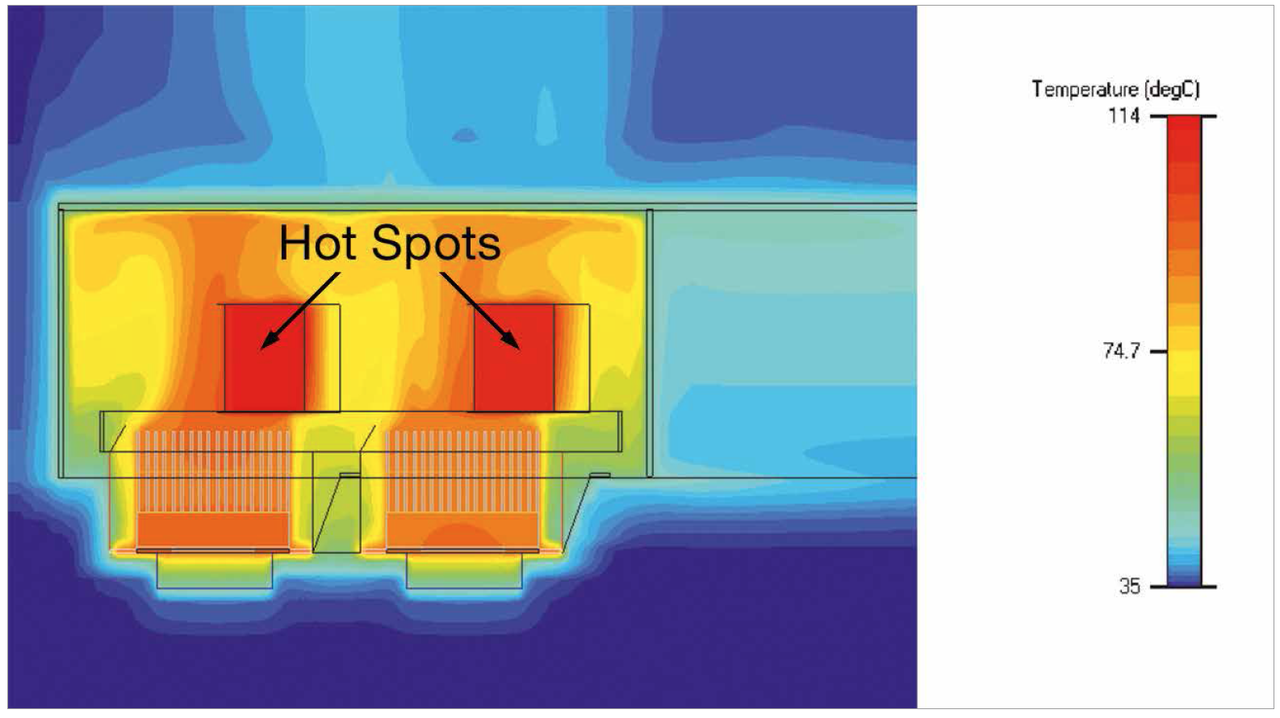

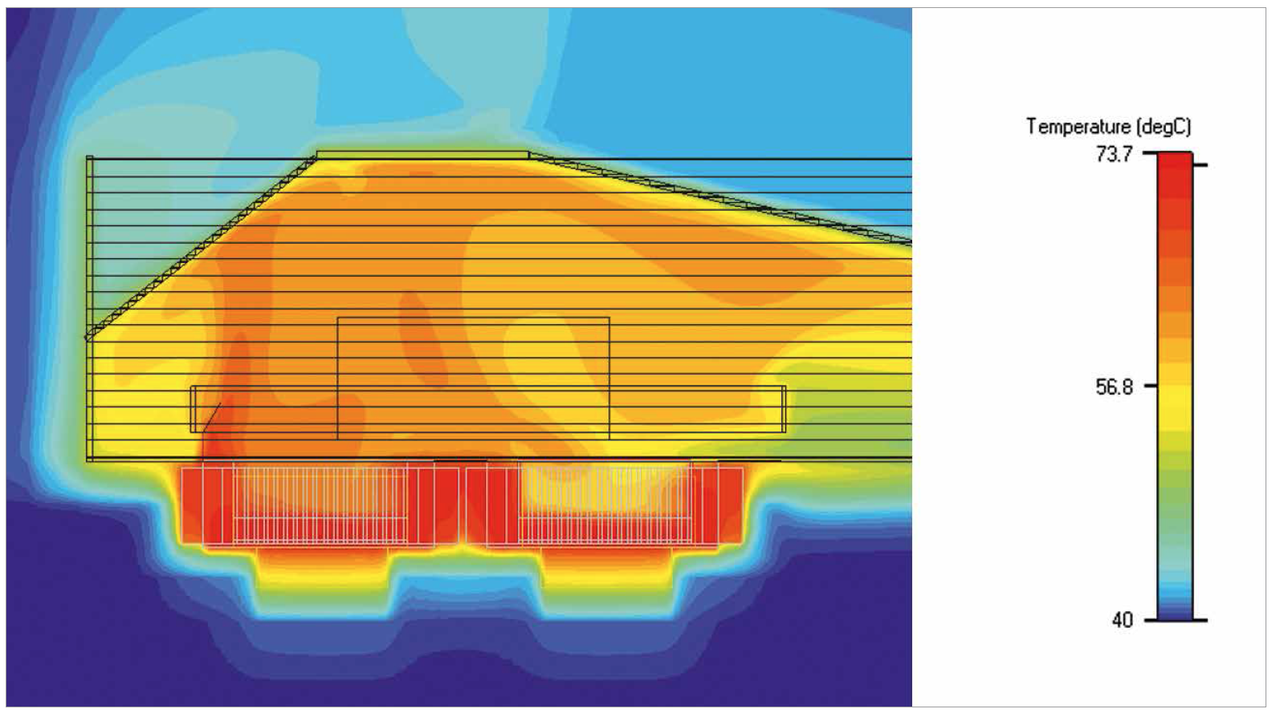

Heat dissipation is extremely important for LED luminaires. A critical issue for LED lighting and cooling is the very high heat fluxes coming from the LED semiconductor devices. Thermal engineering, simulation and analysis can be complex for some luminaires. Design firms and EMS companies can leverage years of experience with thermal design for high performance computing and telecommunications products, at times incorporating some of the same thermal dissipation techniques. For some products, careful design of the PCB and product housing using passive heat dissipation techniques will help. The hot spots in an LED luminaire are normally located in the DC-DC converters and the LED components. Maximizing the size of thermal pads laminated onto the PCB in the locations of the hot spots will route heat away from the components. Providing thermal pathways in the form of thick planes of copper in the PCB will allow heat to be conducted away from hot spots. Maximizing the metal to metal transfer from the PCB to the aluminum outer product casing provides effective heat dissipation allowing the components to operate in a way that maximizes the life of the product. Finally, outer casing design using aluminum formed to allow maximum heat dissipation through the product housing to the air will eliminate the need for separate heat dissipation systems. This ensures that heat can be quickly removed from individual LED components, increasing the life of these products. Figure 1 shows a thermal analysis for an original LED product design where the hotspots were in excess of 100°C. In this case the housing was redesigned, leveraging PCB technology and thermal engineering experience from industrial products designed previously. The resulting thermal performance of the improved design can be seen in figure 2, achieving peak temperatures of less than 70°C.

Figure 1: Thermal analysis of LED Lighting System showing initial hotspots in excess of 110°C

Figure 1: Thermal analysis of LED Lighting System showing initial hotspots in excess of 110°C

Retail and exterior LED lighting applications each present unique design challenges. Different areas in a supermarket will require different color LED lighting systems to enhance product appearance. For example, the fresh produce will benefit from being lit with slightly different color hues depending on the color of the fruit or vegetable. The LED lighting can be designed so that this color temperature (i.e. the hue) can be controlled remotely. Both retail and exterior lighting applications need different numbers of LED lighting units depending on the lighting intensity required and the size of the area to be covered. Designing one PCBA (Printed Circuit Board Assembly) to accommodate different LED colors and numbers of LEDs allows the color variation and quantity to be scaled without a huge number of unique PCBs. In this same design, the luminaires and PCBs were designed to be modular and connected with one another in nearly any number, thanks to the inclusion of a standard power rail going through all luminaires. The elimination of multiple PCB types dramatically increases flexibility and reduces costs of manufacturing and inventory.

Figure 2: New design incorporating thermal engineering on the PCB achieves peak temperatures of < 70°C

Figure 2: New design incorporating thermal engineering on the PCB achieves peak temperatures of < 70°C

Where large volumes of LED components are used in exterior high power or retail LED lighting applications, the issue of variation in the LEDs (even those with the same part number) needs to be addressed. LED components vary by color temperature (light wavelength) and light intensity. In a large scale installation such as exterior building lighting or a supermarket it is important to ensure a consistent color temperature and intensity. The larger the lighting installation the more complex this challenge becomes. Assembly processes must be designed to carefully select LED components for placement in specific areas of the PCB according to the LED manufacturers binning rules. Compliance with the rules should eliminate the potential for imbalanced light and shadow. Software is required to manage this selection and placement process when large quantities of LEDs are involved. Functional test processes typically verify that a finished product is performing to specification. Designing the functional test process to measure color intensity, color temperature and emissive chromaticity will ensure that the finished product meets specification and that balanced light is achieved in compliance with the manufacturers binning rules. Optical sensor technology is integrated into functional testers to make these measurements. The testers are implemented in a black box to eliminate the interference from ambient light. This component selection and test process, coupled with a design that optimized the distance between LED sources, will result in a product with the desired color hue, no shadowing and balanced light.

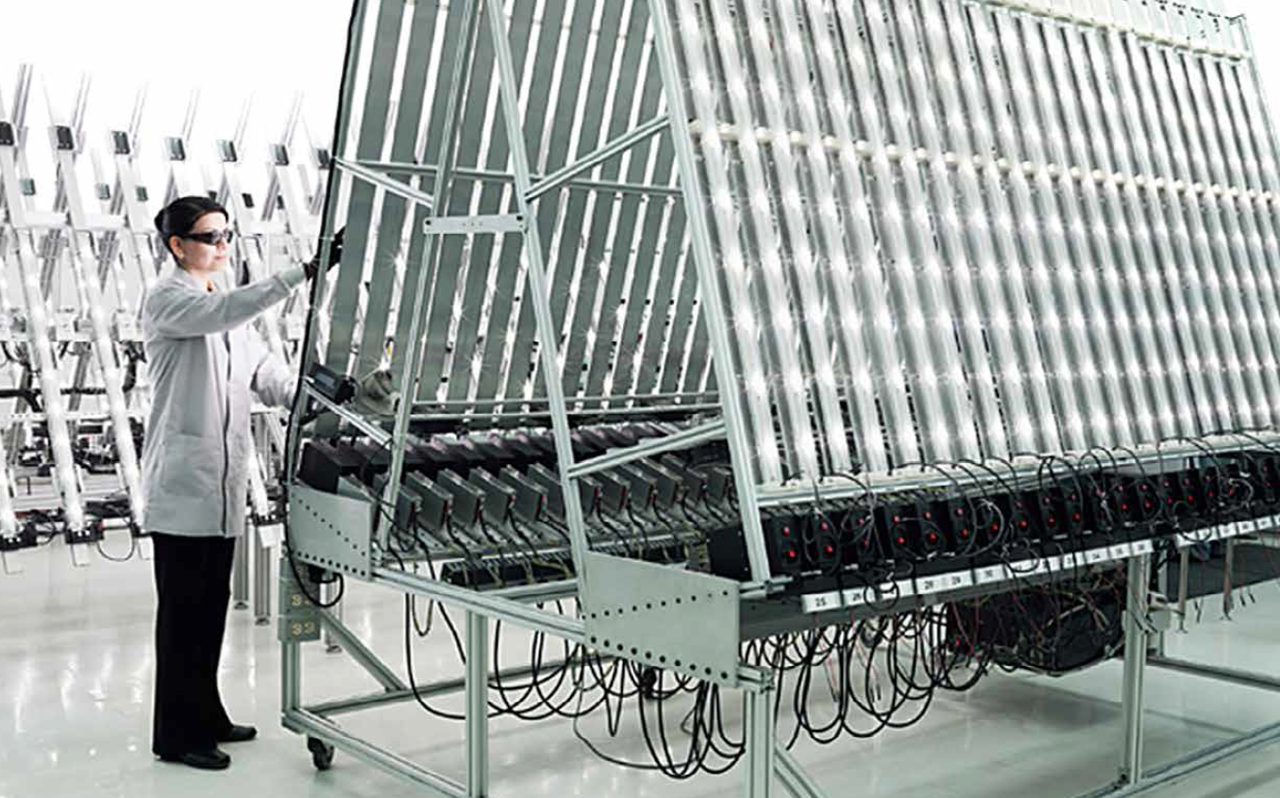

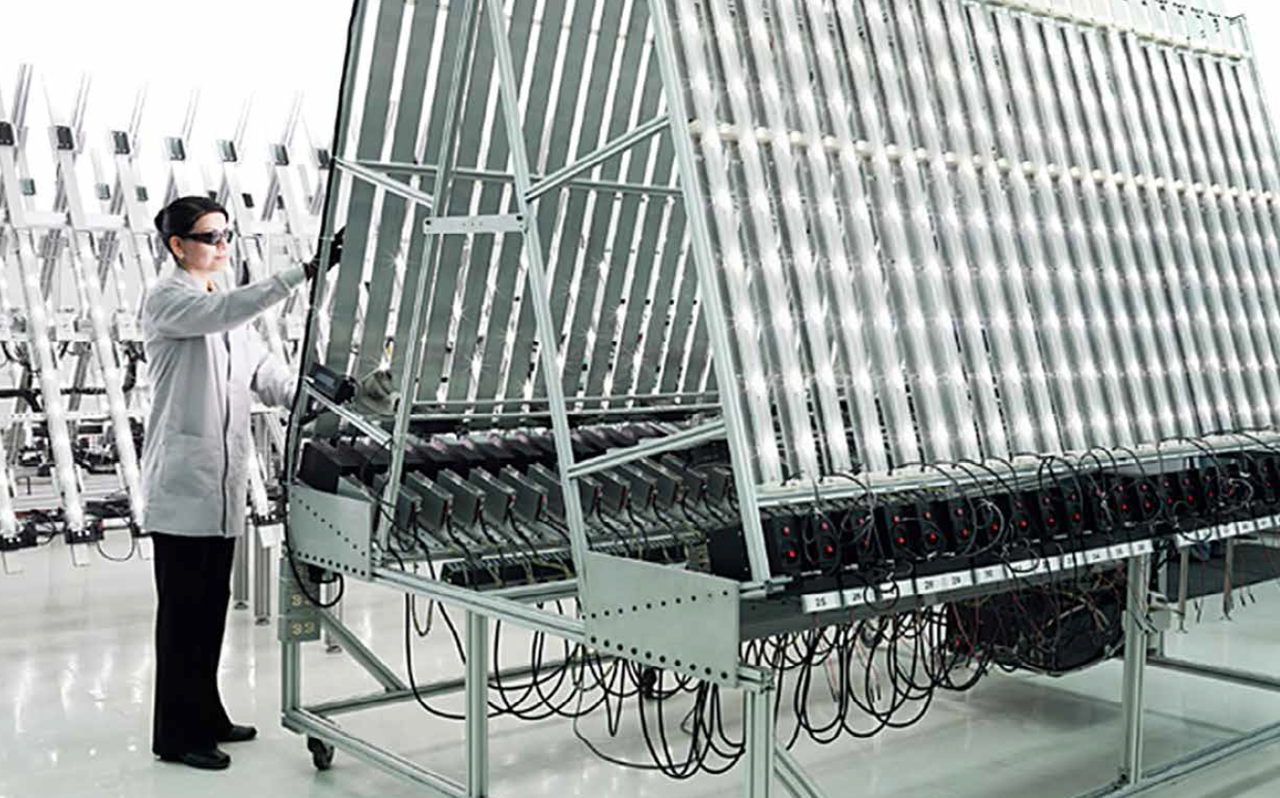

Figure 3: LED functional test and burn-in facility for LED luminaires

Figure 3: LED functional test and burn-in facility for LED luminaires

The Unique Issues of Manufacturing LED Lighting Products

Managing the LED binning process, high volume manufacturing automation and managing stress during the manufacturing process are some key challenges in manufacturing LED lighting systems.

Lighting building exteriors and fitting out large retail stores with LED lighting requires large numbers of LED lighting products. Achieving high quality and reliability in high-volume can be helped by the sensible application of manufacturing automation. The sub-assembly and finished product functional test process is one area where process automation can provide a significant return on investment. The inherent variability in intensity and color temperature in LEDs, together with requirements for testing in environments where ambient lighting can be controlled, necessitate a custom automated test and burn-in solution. Engineers developed such a solution to automate, test and burn-in up to 100 LED luminaires at a time. The system monitors the intensity and wavelength of light from the luminaires and provides pass / fail feedback to production staff, as well as an automated electronic archive of all test results.

LED components are particularly susceptible to stress fractures which can be induced during manufacturing. When high volumes of LED lighting PCBAs and modules are manufactured, the probability of inducing stress related failures can increase. Sometimes, these fractures are very small and cannot be seen by a simple visual inspection, but they can shorten the expected lifetime or reliability of the finished product. Careful design, planning and monitoring of the manufacturing processes eliminate the possibility of stress induced failures. The design of carriers used during manufacture, handling equipment and monitoring equipment are all important. Using LEAN principles in the design of manufacturing lines can help minimize the path products need to travel. This reduces opportunities for handling and vibration to cause damage. Some processes used in PCBA manufacture such as de-penalization can cause shock, stress or vibration to LED components. Traditional methods of de-penalization such as scoring, snap-off or routing are sufficient for many components, however the micro lens and ceramics materials in LEDs require more sophisticated de-penalization. One way to eliminate the potential for such damage is to use a numerically controlled milling robot to separate the PCBAs from the panel. All of these factors are taken into consideration when designing the manufacturing processes and tooling for high volume LED lighting products. Manufacturing control systems that provide component, sub-assembly and product traceability together with stress measurement monitoring are also an important part of the manufacturing process design.

Managing the Complex Supply Chain

In the LED market space it is estimated that there are over 2,000 component providers and manufacturers of LEDs, packages and luminaires in China alone. The LED luminaire supply chain includes many of the traditional suppliers, such as LED, driver and integrated circuit companies. It also includes specialist LED and lighting companies as well as suppliers of custom components such as extruded aluminum, plastic parts and PCBs. Supply chain design and management is really a cross-functional and concurrent process that starts during design and continues throughout the product lifecycle. There are many aspects to the supply chain design including supplier capability assessment, component engineering analysis along with commercial considerations.

Supplier capability assessment is particularly important for the custom components included in a design. Access to and knowledge of standard electronic component manufacturers and products is important. However, it needs to be combined with a careful assessment of the suppliers who will provide the custom components. Partners with in-house capabilities such as PCB design and fabrication, precision machining, metal fabrication, aluminum extrusion and plastic injection molding help simplify the supply chain.

Component engineers analyze a bill of materials from a technical, cost and risk mitigation standpoint. Alternative components are compared to determine suitability based on the overall product specification and component cost at various volumes. Risk analysis is also undertaken to identify components where only a single source is available. Multiple sources for the same component allow better risk management of the supply chain both at the design stage and volume production. In some EMS companies the component engineers also have access to applications engineers at the component manufacturer and can assess knowledge about the stage of the component in its own lifecycle; that is, is that component likely to become obsolete. This process allows component engineers to make technical recommendations to design engineers and commercial recommendations to supply chain management.

Supply chain management should be concerned not just with pure component cost. Other key factors such as risk mitigation and flexibility are very important when building a robust supply chain. Choice of supplier and selection of dual or multiple sources should take into account, along with the end market geography for the luminaire, the logistics and import/export costs and duties throughout the supply chain. All of these elements contribute to the total landed cost. Shorter lead-times and multiple component sources allow a supply chain to respond to the revenue opportunities associated with unforeseen demand. This flexibility is important in the LED lighting market where the selection of the luminaire vendor may depend on their ability to deliver in high volume on short notice. A rigorous analysis of total landed cost together with lead-time analysis and the creation of multiple sources for critical components will result in a much more robust supply chain.

Conclusions

OEM LED lighting companies seek a fully integrated solution for manufacturing, with design services and a global supply chain. Working with partners having experience with LED luminaires is essential. In addition, if they also have experience in other relevant industries and technologies, these partners can provide differentiated competitive advantages in product performance, cost, time to market and global supply chain.